1, lithium battery ultrasonic metal spot welding

Because the positive ear of the lithium battery cell is an aluminum strip, it is not possible to directly solder, so it is necessary to add a nickel strip, usually using ultrasonic metal spot welding method: The application of ultrasonic waves to produce high frequency oscillation between the friction part of the two metal sheets produce high heat, and the fusion and connection. Frequency: 20K~35KHZ Time: about 0.3/S

Avoid over-welding of the positive aluminum strip, otherwise it is easy to break. Avoid the positive aluminum strip welding is not strong, otherwise the battery is easy to power off.

2, lithium battery solder connection

Main principle: Apply the soldering iron to heat the solder wire to condense, so that the tin material is attached to the welded part, and it is connected after cooling.

1) Soldering iron classification:

A. Internal heat type and external heat type, internal heat type soldering iron heating up fast.

B. Ordinary soldering iron, temperature control iron, anti-static constant temperature soldering iron.

2) Soldering iron power: 30W, 35W, 40W, 50W, 55W, 60W, 65W, etc.

3) Soldering iron temperature: according to the solder area and the amount of tin set, the temperature is too low can not quickly coagulate the tin line, affecting the welding speed, the temperature is too high, the solder joint is not lubricated. The soldering iron temperature is generally set at 360 ° C ±10 ° C

4) Welding posture: generous and natural, sitting upright.

5) Welding technique: there are pen holding method and straight holding method.

6) Welding Angle: The welding Angle of the pen holding method is between 30° and 60°, and the Angle is 45° between the tip of the iron and the object to be welded.

7) Solder composition: Tin (Sn) 60-63%, lead (Pb) 40-37%, rosin 1.0%~1.2%

8) Welding time: <3S

9) Method: First put the soldering iron on the part to be welded, and then put the tin line on the gap between the soldering iron head and the part to be welded.

10) Welding amount: can cover the solder object can be the right amount of tin 10) welding quality: solder joint bright average, strong, no tin, missing welding, no false welding, no porosity, no layer. The size of solder joint is related to the amount of hot tin in contact.

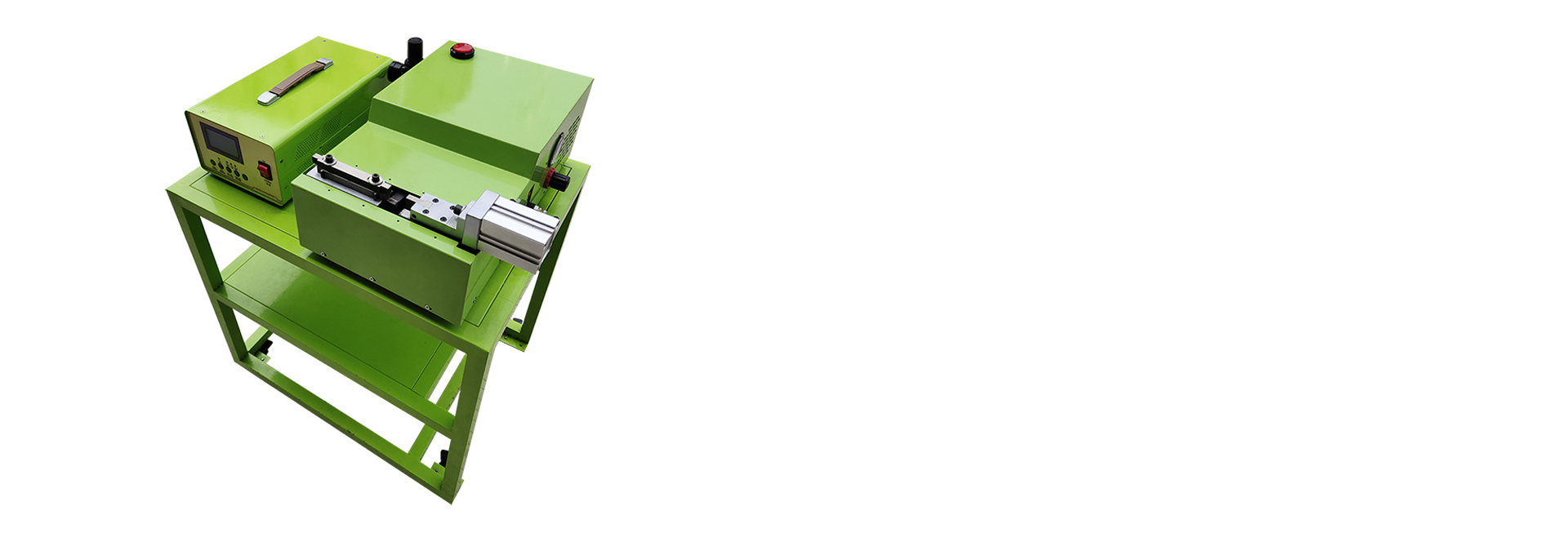

3, lithium battery shell super welding process and requirements

1) The package and connection of the shell are generally welded by ultrasonic plastic.

2) Working principle: The application of ultrasonic wave to produce high-frequency oscillation between the upper and lower shell friction, part of the temperature rise to produce high heat, the two rubber parts will produce data between the "plastic flow", solidified under pressure, and constitute welding.

3) Select suitable ultrasonic welding machine,

4) Use the appropriate welding parameters: power elements: force × speed, force pressure (air pressure), falling speed. Rate has frequency and amplitude, energy = power × time frequency: 20KHZ welding time, holding time.

5) The design of the shell and maintenance board should pay special attention to the size of the match, in order to avoid excessive or excessive tightness.

6) The thickness of the maintenance board and the layout of the components should be fully considered the influence of ultrasonic to avoid the components being shaken loose.

7) Affect the welding effect: plastic materials, welding design, mold, etc.

8) Super welding quality: no super damage, no glue, no super high, average welding line, tight welding, the sample fell to the board at 1m height, X, Y, Z sides fell once (a total of six times) fit the request.

中文(简体)

中文(简体)

Wechat

Wechat